Concrete Driveway in Urbandale IAUrbandale Concrete - concrete driveway in Urbandale, IA

Concrete is a highly sought-after driveway material for many reasons, such as its durability, longevity, and low maintenance requirements. With its ability to withstand substantial force and its excellent value for the money, it is no wonder why this material is a popular choice for driveways. While it is true that concrete is more costly than gravel and asphalt, it is a far more cost-effective option than opting for a driveway covered in brick, cobblestone, or concrete pavers. In addition, it can even outlast these materials in most cases. Although plain concrete may seem dull and uninspiring, it can be tinted and embossed to create a beautiful, unique look that will stand out and draw attention. With creativity, plain concrete can easily be transformed into a visually appealing and captivating surface. |

|

Installation

Although homeowners may pour a concrete driveway themselves, it is challenging. Time is an essential factor since concrete quickly hardens after it is poured. As a result, it is better left to specialists who can swiftly excavate, create forms, pour concrete, and finish the surface. Experienced professionals from Urbandale Concrete may complete the process in a few days. In contrast, a homeowner often takes a week or more for excavation and preparation, followed by another long day for pouring and finishing. A crew of eager and non-disabled volunteers is required for the homeowner who is brave enough to pour his concrete.

Installing a concrete driveway begins with removing grass and other plants and establishing a firm soil foundation. After that, wood forms are constructed along the perimeter of the desired driveway. Next, a base of at least 4 inches thick class-5 gravel is added, graded, and compacted. Above the packed gravel base, the reinforcement material is added as a steel wire grid or metal rebar arranged in a crisscross pattern throughout the region.

The driveway is fully complete and ready for the concrete pour. Typically, a crew of several people works swiftly to fill the forms with wet concrete as it is delivered from a ready-mix provider and finishes the surface quickly. The finishing crew should also ensure a suitable number of expansion joints—grooves produced across the wet surface at predetermined intervals to allow the slab to shift and crack at regulated locations. A slab can break randomly without expansion channels due to natural settling and displacement.

Floating concrete is an essential aspect of the finishing process. After the concrete has been poured and polished, the finishing crew works the surface of the concrete with various equipment, bringing the cement and finer particles to the surface through capillary action to create an appealing, smoother texture. The quantity of floating decides how smooth the surface will be. It takes some skill to do so because too much floating will weaken the surface and cause it to flake, while too little will leave the slab with a rugged, industrial appearance. This is also when a competent staff can apply decorative finishes and colors to the slab's surface.

After all of the labor is completed, one of the essential parts of a concrete driveway installation begins: curing. Concrete does not dry out; instead, it goes through a

lengthy chemical process that hardens and strengthens it. This curing process must take place under ideal conditions. It all starts with the weather. The perfect curing temperature is 70 degrees Fahrenheit, with a damp surface but not wet. Curing will take longer in chilly conditions. The surface should be moistened with water frequently in hot weather to slow down the curing process.

Although homeowners may pour a concrete driveway themselves, it is challenging. Time is an essential factor since concrete quickly hardens after it is poured. As a result, it is better left to specialists who can swiftly excavate, create forms, pour concrete, and finish the surface. Experienced professionals from Urbandale Concrete may complete the process in a few days. In contrast, a homeowner often takes a week or more for excavation and preparation, followed by another long day for pouring and finishing. A crew of eager and non-disabled volunteers is required for the homeowner who is brave enough to pour his concrete.

Installing a concrete driveway begins with removing grass and other plants and establishing a firm soil foundation. After that, wood forms are constructed along the perimeter of the desired driveway. Next, a base of at least 4 inches thick class-5 gravel is added, graded, and compacted. Above the packed gravel base, the reinforcement material is added as a steel wire grid or metal rebar arranged in a crisscross pattern throughout the region.

The driveway is fully complete and ready for the concrete pour. Typically, a crew of several people works swiftly to fill the forms with wet concrete as it is delivered from a ready-mix provider and finishes the surface quickly. The finishing crew should also ensure a suitable number of expansion joints—grooves produced across the wet surface at predetermined intervals to allow the slab to shift and crack at regulated locations. A slab can break randomly without expansion channels due to natural settling and displacement.

Floating concrete is an essential aspect of the finishing process. After the concrete has been poured and polished, the finishing crew works the surface of the concrete with various equipment, bringing the cement and finer particles to the surface through capillary action to create an appealing, smoother texture. The quantity of floating decides how smooth the surface will be. It takes some skill to do so because too much floating will weaken the surface and cause it to flake, while too little will leave the slab with a rugged, industrial appearance. This is also when a competent staff can apply decorative finishes and colors to the slab's surface.

After all of the labor is completed, one of the essential parts of a concrete driveway installation begins: curing. Concrete does not dry out; instead, it goes through a

lengthy chemical process that hardens and strengthens it. This curing process must take place under ideal conditions. It all starts with the weather. The perfect curing temperature is 70 degrees Fahrenheit, with a damp surface but not wet. Curing will take longer in chilly conditions. The surface should be moistened with water frequently in hot weather to slow down the curing process.

The Pros of Concrete Driveways

Maintenance

Concrete driveways require little maintenance. Still, keeping the driveway clean and sealed is vital to preserving its longevity. Vigorous scrubbing with a hose and sharp brush will typically suffice, and concrete sealant will offer an extra layer of protection. At least once a year, the sealer should be applied. If you live in snow country, sealing a driveway in the fall ensures that the slab will withstand road salts and brutal winter weather.

Longevity

Concrete driveways often last 25 to 50 years, depending on how well they were built and how well they have been maintained. Concrete is the most popular material used for driveways due to it's longevity and ease of maintenance. Have the pros pour it once, and you won't have to think about it for decades.

Concrete driveways require little maintenance. Still, keeping the driveway clean and sealed is vital to preserving its longevity. Vigorous scrubbing with a hose and sharp brush will typically suffice, and concrete sealant will offer an extra layer of protection. At least once a year, the sealer should be applied. If you live in snow country, sealing a driveway in the fall ensures that the slab will withstand road salts and brutal winter weather.

Longevity

Concrete driveways often last 25 to 50 years, depending on how well they were built and how well they have been maintained. Concrete is the most popular material used for driveways due to it's longevity and ease of maintenance. Have the pros pour it once, and you won't have to think about it for decades.

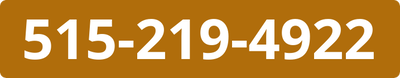

If you're looking to install a beautiful and durable concrete driveway, you've come to the right place. At Urbandale Concrete, we have the expertise and years of experience to ensure that you get exactly what you need. We'll provide you with the highest quality product, expert installation, and unbeatable customer service, so you can have the perfect driveway that will last for years to come. So contact us today to get the best concrete driveway in Urbandale, IA!